It’s tough. It looks great. And it lasts a long, long time. In addition to being durable, powder coating is an attractive choice due to many environmental advantages.

What is Powder Coating?

Powder coating is a high-quality finish found on thousands of products you come into contact with every day. Powder coating protects the roughest, toughest machinery as well as many of the household items we depend on daily. It provides a more durable finish than liquid paints can offer, while still providing an attractive finish. Powder coated products are more resistant to diminished coating quality as a result of impact, moisture, chemicals, ultraviolet light, and other extreme weather conditions. In turn, this reduces the risk of scratches, chipping, abrasions, corrosion, fading, and other wear and tear issues.

How it Works

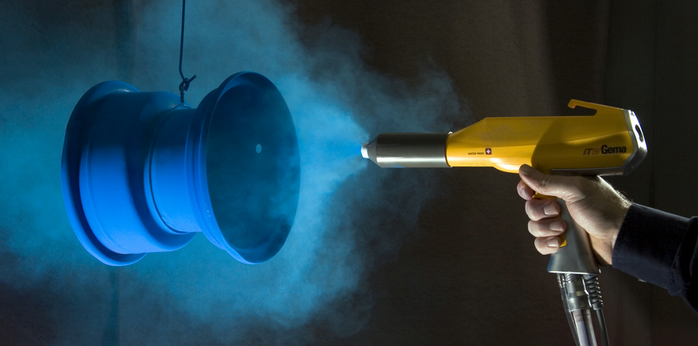

Powder coatings are based on polymer resin systems, combined with curatives, pigments, leveling agents, flow modifiers, and other additives. These ingredients are melted, mixed, cooled, and ground into a uniform powder similar to baking flour. A process called electrostatic spray deposition (ESD) is typically used to achieve the application of the powder coating to a metal substrate. This application method uses a spray gun, which applies an electrostatic charge to the powder particles, which are then attracted to the grounded part. After application of the powder coating, the parts enter a curing oven where, with the addition of heat, the coating chemically reacts to produce long molecular chains, resulting in high cross-link density. These molecular chains are very resistant to breakdown. This type of application is the most common method of applying powders. Powder coatings can also be applied to non-metallic substrates such as plastics and medium density fiberboard (MDF).

Types of Powder Coating

There are two main categories of powder coatings: thermosets and thermoplastics. The thermosetting variety incorporates a cross-linker into the formulation. When the powder is baked, it reacts with other chemical groups in the powder to polymerize, improving the performance properties. The thermoplastic variety does not undergo any additional actions during the baking process, but rather only flows out into the final coating.

With any questions concerning powder coating, contact PES-Solutions with the link below.

Great post. Your site is a good source of info about this topic, I enjoy reading section. More power to you~