Proper operation and maintenance of the building chillers should be a high priority in any facility energy management program. Inefficient or ineffective operation or maintenance can result in higher energy costs, lower system performance and reliability, and decreased equipment life. We will discuss common chiller problems and chiller repair solutions we offer.

Common Problems with Chillers and Solutions

Poor Operating Practices and Chiller Repair Solutions

Poor operating practices not only can decrease the chiller efficiency, but also chiller life. Most such practices are the result of one or two situations:

- trying to get a chiller to do something that it was not designed to do

- not understanding the consequences of a particular action

For example, one common practice is to increase the rate of chilled water flow through the chiller. The belief is that with a higher flow rate, more cooling water will be available. In reality, however, increasing the flow rate through a chiller beyond the manufacturers stated limit actually reduces the operating efficiency of the chiller.

Equally important, flow rates higher than those recommended increase the rate of erosion in the chiller’s tubes. Therefore, leading to early tube failure.

In addition, PES offers chiller repairs to increase chiller efficiency. Through our coating process, we remove any bad metals or blemishes that occurred due to poor operating practices.

Maintenance of Chillers

Good maintenance practices are important to the efficient operation of all building equipment. However, there are few areas where this is more evident than in the maintenance of building chillers. Most new, high efficiency centrifugal chillers carry a full-load efficiency rating of approximately .50 kW per ton.

If that chiller has proper maintenance, in five years it can have a full-load efficiency of .55-.60 kW per ton. Annually, this means that a poorly maintained chiller will use 20-25 percent more energy. Regularly schedule inspections and recording maintenance logs is a vital operation. This helps to keep things in check, and saves you money in the long run. Our team can also remove any bad metals and blemishes to reduce time spent on maintenance.

Corrosion of Chillers

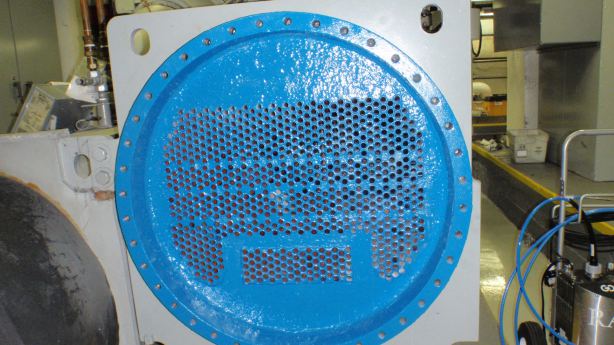

Most chiller tubes are copper, and experience galvanic corrosion due to two metals being dissimilar. The corrosion and loss of carbon steel can affect the performance of the chiller. This is due to poor water flow issues and sediment buildup. Therefore, this will eventually lead to perforation of the tube and refrigerant loss. We offer chiller repairs to these common problems.

If you have a chiller with corrosion, we have a chiller repair services for you. Our coating process removes bad metals or blemishes.

PES Chiller Repairs Services

We can coat your components of your chiller with an epoxy solution. We begin by abrasive blasting the parts affected to remove any bad metals or blemishes. Then, we apply our epoxy to said parts using our product: PES 101 Power Metal Paste. This paste is a two component solvent free epoxy metal repair compound. The machining and curing of this takes as little as 1.5 hours. For a full load on this epoxy, it is best to wait 2 days.

At PES we carry a large array of products to get your machinery working to prevent downtime and dissatisfaction. We offer the best warranties in the market. Contact us with the link below for more information!

That article was amazing, I am very much impressed with your thoughts. I got the best information from this site of the blog, It’s very useful to all and us. Thanks for sharing this post.

Hi sir good morning kam rabbani from kakainada I have some problem for water chiller machine 1ton water chiller machine