PES 301 Epoxy Resin and Hardener is a two component thixotropic solvent free epoxy material for application on manually prepared surfaces. The following is just one job we did using PES 301 application and the steps we followed.

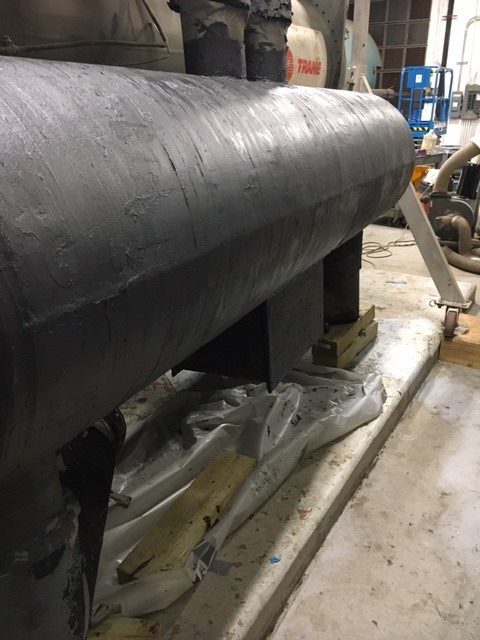

This chiller is a large 1120 Ton Trane model. Freon gases were leaking from a previously welded patch on the bottom of the Economizer, which was originally caused by CUI, Corrosion Under Insulation.

PES 301 Application

Step 1: Removal of Insulation

This vessel, called an Economizer, is a key component of a large chiller to cool class rooms in a University. Insulation was removed and revealed metal loss and a crack in a previously welded patch. A dust proof tent was erected. Then, the economizer was abrasive blasted to a NACE standard #2 near white metal with a 3-4 mil angular anchor pattern.

Step 2: Vacuum Application and Cold Welding using PES 101 Power Metal and reinforcing fabric

In the past, a patch was welded to the bottom of the economizer, which had started leaking. After metal was blasted, a vacuum was applied to the vessel. Then, a new patch was cold welded to the bottom of the economizer using PES 101 Power Metal and reinforcing fabric. This entire vessel was coated with a layer of PES 180 structural adhesive with fiberglass mesh installed.

Step 3: Light Sanding and Application of Fiber Glass Mesh

After first layer of PES 180 and reinforcing fabric had set up, the entire surface was lightly sanded and two more layers of fiber glass mesh were applied using PES 301 epoxy resin and hardener.

We started at one end making 2 complete wraps, then moving to the other end with a 50% over lap on each wrap, then repeating this step one last time for a total of 3 wraps.

One other great quality of PES 301 as a solvent free repair material is the fact that it is used instead of fiberglass resins such as polyester resins & vinyl ester resins. These have solvents in them and when the Quality of the Air in a facility, or on a ship, etc. is of most importance, PES 301, 100% solids resins is the best way to go.

Step 4: Application of PES 501 CRSG

Finally, 2 coats of PES 501 CRSG @ 10-15 mils per coat were applied to prevent corrosion under the insulation from happening in the future.

For further information, contact PES using the link below!