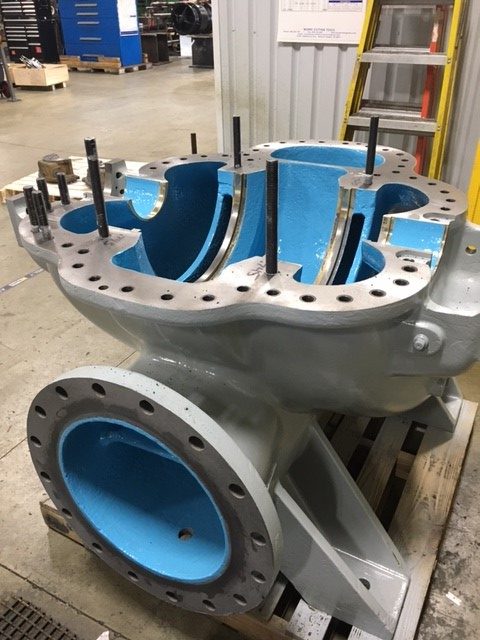

PES 203 Super Flow Ceramic Fluid is a two component solvent free epoxy metal repair fluid designed for use on a wide range of metallic surfaces subject to cavitation, low particulate abrasion and impact. The product is suitable for emergency repairs or part of planned maintenance to equipment such as worn impellers, damaged valves, damaged pump casings, eroded pipe work, A-frames and rudders. Once cured, the material has a high gloss finish ensuring flow efficiency gains for the equipment and components coated in the material.

PES 203 Super Flow Ceramic Fluid

Main Characteristics

- Two component

- Solvent free epoxy

- Usable life 20 minutes @68°F (20°C)

- Touch dry 90 minutes @ 68°F (20°C)

- Full cure 60 days @ 68°F (20°C)

- 100 Rockwell R Hardness (Once fully cured)

- Applied by brush or applicator tool

- Available in 500gm, 1kg, 3kg, 30kg pack sizes (570kg/cm²)

Mechanical Properties

Adhesion

Tensile Shear to ASTM D1002 – 2650psi (187kg/cm²)

Compressive Strength

Tested to ASTM D 695 – 10,450psi (735kg/cm²)

Corrosion Resistance

Tested to ASTM B117 – Minimum 5000 hours

Flexural Strength

Tested to ASTM D790 – 8100psi

Heat Resistance

Suitable for water immersion up to 158°F(70°C) and intermittent contact with steam up to 248°F(120°C). Dry heat.

Fluid Flow Protection Using PES 203

For more information on our PES 203 Super Flow Ceramic Fluid, contact PES using the link below!