PES 103 D TDS: Metal Repair Epoxy Putty Stick

PES 103 Putty Stick PES 103 Epoxy Putty Stick is a two component repair material in stick form which cures rapidly at room temperature after mixing. It is a metal repair adhesive which develops high mechanical strength in a short period of time. 1. Typical Applications The Epoxy Putty Stick is suitable for emergency repairs…

PES 103 Putty Stick PES 103 Epoxy Putty Stick is a two component repair material in stick form which cures rapidly at room temperature after mixing. It is a metal repair adhesive which develops high mechanical strength in a short period of time. 1. Typical Applications The Epoxy Putty Stick…

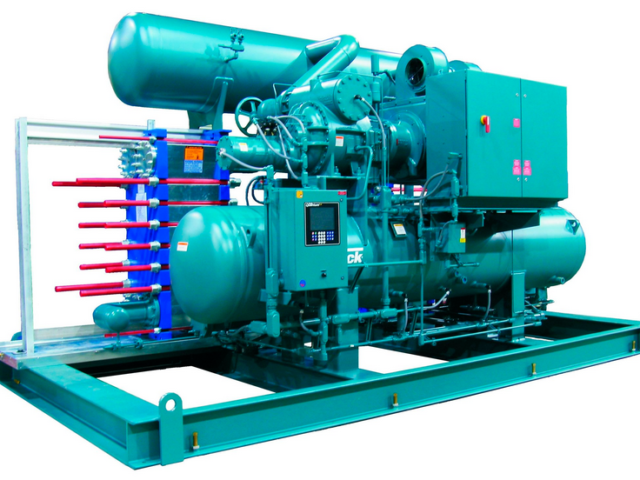

View moreA chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. This liquid can then be circulated through a heat exchanger to cool air or equipment as required. As a necessary byproduct, refrigeration creates waste heat that must be exhausted to ambient or,…

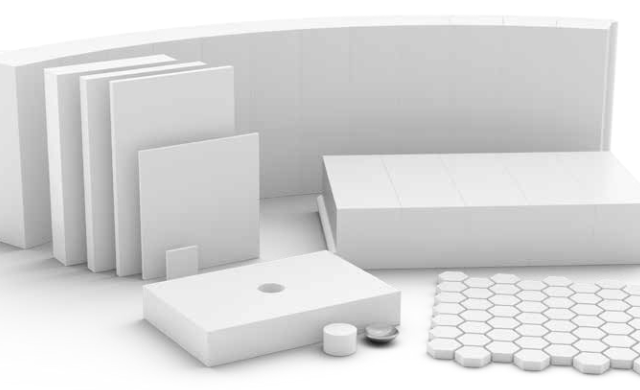

View moreCeramics have been used by the power industry for years as a cost-effective, wear-resistant material. Ceramic material gives continuous protection to fan linings, chute liners, hopper bottoms, and dozens of other stationary high-wear points. Now, the technology is available for using ceramics on moving parts as well. In this article…

View moreWhat is Fluid-Gas desulfurization (FGD)? Fluid-gas desulfurization is a set of technologies used to remove sulfur dioxide (SO2) from exhaust flue gases of fossil-fuel power plants, and from the emissions of other sulfur oxide emitting processes. What are Fluid Gas Desulfurization Systems? Wet Scrubbers remove dust particles by capturing them…

View moreHere you will find the following Data Sheets. Non-Metallic Expansion Joints 01 Non-Metallic Expansion Joints 02 Non-Metallic Expansion Joints 03 Non-Metallic Expansion Joints 04 Series 320M

View moreHere you will find the following Data Sheets. PES 00 Series Intros Data Sheets PES 100 Series Data Sheets PES 200 Series Data Sheets PES 300 Series Data Sheets PES 500 Series Final Data Sheets PES 600 Series Data Sheets

View morePES A Introduction Leaflet PES B Checklist Prior to Application PES C Checklist for steel preparation PES D Surface Prep Standards PES E surface prep guide PES F introduction PES G comparison list

View moreHere you will find the following Data Sheets. PES 101 PES 101.102 A Comparison Chart Belzona Thortex-6 PES 101 B Power Metal PL PES 101 C PS Metal Repair Paste PES 101 D TDS Metal Repair paste PES 101 MSDS Metal Repair Paste Kit PES 101 G Metal Repair Systems…

View more201 Ceramic Repair Paste PES 201 PL Ceramic Repair Paste PES 201 – 201 / 202 Comparison Chart Belzona / Thortex PES 201 PS Ceramic Repair Paste PES 201 TDS Ceramic Repair Paste PES 201 SDS Ceramic Repair Paste Kit 202 Ceramic Repair Fluid PES 202 Ceramic Repair Fluid PL…

View more301 Epoxy Resin and Hardener PES 301 A PL Epoxy Resin and Hardener PES 301 B 75PSI. Method Statement PES 301 C 100PSI. Method Statement PES 301 D TDS Epoxy Resin and Hardener PES 301 MSDS Epoxy Resin and Hardener Kit PES 301 G Emergency Temporary Pipe Repair Guidelines PES…

View more