Expansion joints are extremely important because they allow for the accommodations of temperature changes. Changes in temperature can cause problems or destruction. There are a few different types of expansion joints, this article will discuss high temperature expansion joints specifically. PES uses HOLZ Rubber Company's high temperature expansion joints engineered…

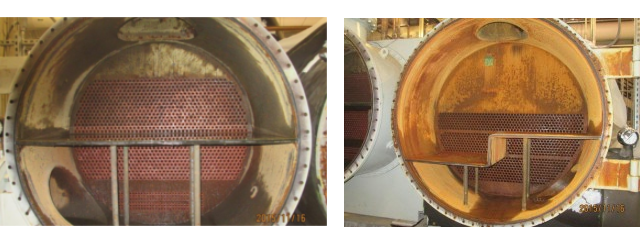

View moreWith cool weather upon us, now is the time to have maintenance on your building's chilled water system. If your chiller, condensate pans or cooling tower could use a coating system to protect and preserve your equipment, contact us today! We probably already work for your chill water maintenance provider, Carrier,…

View moreExpansion joints are extremely important because they allow for the accommodations of temperature changes. Changes in temperature can cause problems or destruction. There are a few different types of expansion joints, this article will discuss piping expansion joints specifically. Every scenario is different and every environment is also different. Although…

View moreExpansion joints are extremely important because they allow for the accommodations of temperature changes. Changes in temperature can cause problems or destruction. There are a few different types of expansion joints, this article will discuss flue duct expansion joints specifically. Having the right flue duct expansion is extremely important to…

View moreWhen you are planning an epoxy coating project, it is important to choose the right epoxy coating that best suits your needs. Epoxy coatings are available in a variety of thickness and styles that can be customized to meet your requirements for durability, functionality and aesthetics. PES Solutions can help…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Secondary Containment Liners…

View moreAre you confused about the federal secondary containment regulations? We know how mind-numbing this stuff can be. This is why we are going to break it down for you in this article. These are the top 5 main points we think it is consider under the EPA's hazardous waste storage…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Corrosive Environments The…

View moreExpansion joints are extremely important because they allow for the accommodations of temperature changes. Changes in temperature can cause problems or destruction. This article will discuss some of the basics of expansion joints. Types of Expansion Joints Types of expansion joints include: Piping Expansion Joints Flue Duct Expansion Joints High…

View moreIf you have heavy duty pails, drums or totes storing materials at your facility then you should strongly consider secondary containment. A secondary containment serves as reinforcement by means of an outer wall or secondary barrier. Theses containers main function is to prevent contamination and ensure safety. Types of Secondary…

View more