PES Service To HVAC Industry Ceramic Repairs

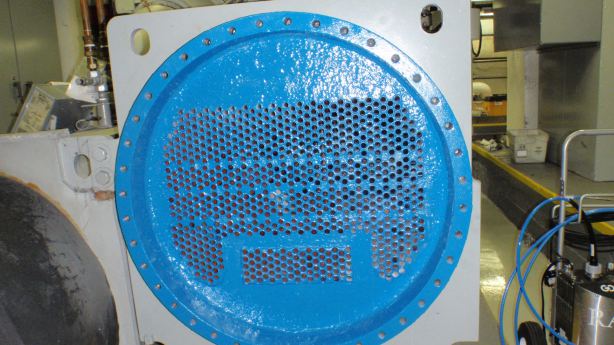

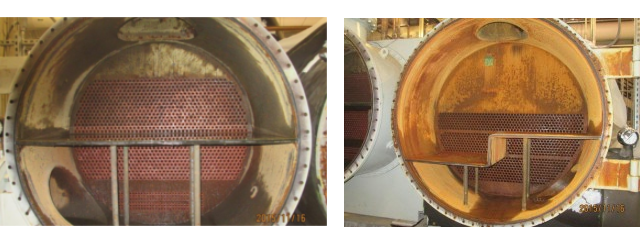

It’s time to tune up and maintain your HVAC equipment Chillers are one of the most important pieces of equipment for your heating and cooling needs. Along with all the mechanical repairs and upgrades, be sure to complete a corrosion / erosion upgrade to your Tube Sheets and assorted wet attachments, such as Water Boxes…

It’s time to tune up and maintain your HVAC equipment Chillers are one of the most important pieces of equipment for your heating and cooling needs. Along with all the mechanical repairs and upgrades, be sure to complete a corrosion / erosion upgrade to your Tube Sheets and assorted wet…

View morePlant Equipment & Services is an HVAC contractor licensed by the state of Texas. We specialize in rebuilding and providing solutions for long term protection of costly corrosion to cooling towers, air handler condensate pans, bearing fits on air handler fan shafts, along with rebuilding and coating chiller tube sheets,…

View morePES-Solutions Cooling Tower Epoxy Coating Services PES is licensed by the state of Texas to do work with cooling towers. We offer services to assist in maintaining your cooling tower, and ultimately expanding the life of the tower. We offer products such as PES 501 and PES 505 to seal…

View moreChiller Repairs: DON'T REPLACE IT – REPAIR IT! Under insulation corrosion found after closed cell foam insulation was removed. PES 180 Structural Adhesive Repair Project Welding steel patches was out of the question. Most HVAC contractors find that welding a patch doesn't work out well because corrosion has eaten away most…

View moreWith years of experience providing Polymeric Engineered Solutions, our team is committed to resolving deterioration and corrosion using our PES products. The following are just a few of the many solutions our PES products have provided. Success Stories Using PES Products Tube & Shell Heat Exchangers & Chillers The Problem: The…

View moreWith cool weather upon us, now is the time to have maintenance on your building's chilled water system. If your chiller, condensate pans or cooling tower could use a coating system to protect and preserve your equipment, contact us today! We probably already work for your chill water maintenance provider,…

View moreProper operation and maintenance of the building chillers should be a high priority in any facility energy management program. Inefficient or ineffective operation or maintenance can result in higher energy costs, lower system performance and reliability, and decreased equipment life. We will discuss common chiller problems and chiller repair solutions we…

View moreCapacity, horsepower and initial and operating costs are all extremely important aspects when selecting a cooling tower, but long term maintenance and care should also be heavily considered. Importance of Proper Cross Flow Metal Cooling Tower Maintenance Properly maintaining your cross flow cooling tower can save you time, money, energy,…

View morePES-Solutions offers many cross flow metal cooling towers services for our clients. We can inspect your cross flow metal cooling tower, make recommendations about improvements to extend the life of your investment and make modifications that allow for more efficiency and easier maintenance. In addition, our team can install a…

View moreWith cool weather upon us, now is the time to have maintenance on your building's chilled water system. If your chiller, condensate pans or cooling tower could use a coating system to protect and preserve your equipment, contact us today! We probably already work for your chill water maintenance provider, Carrier,…

View more