Chiller Repairs: DON’T REPLACE IT – REPAIR IT!

PES 180 Structural Adhesive Repair Project

Welding steel patches was out of the question. Most HVAC contractors find that welding a patch doesn’t work out well because corrosion has eaten away most of the original steel substrate.

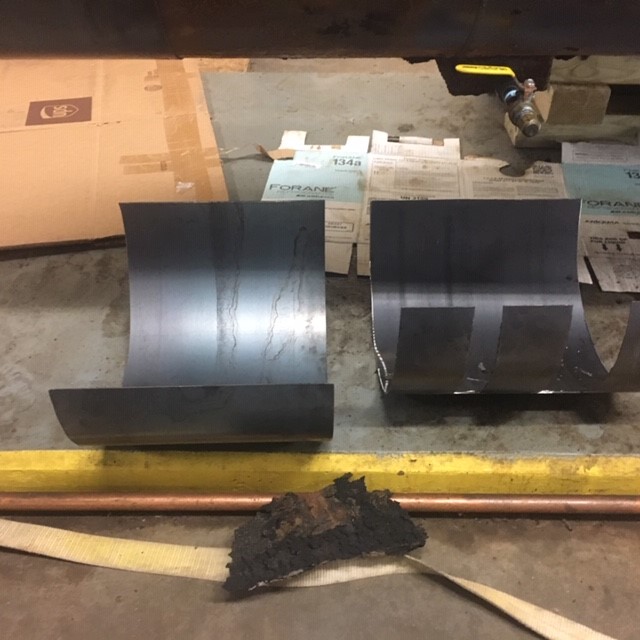

An unconventional repair was necessary. 1/8″ steel was sheared to half the size of the barrel diameter and then rolled to fit the curvature of the barrel. This 15′ long piece was then cut into manageable pieces, dry fitted and trimmed where necessary. A dust proof shelter was built and all parts of the chiller and repair plating were abrasive blasted to a NACE Standard #2 -SSPC-Sp 10 near white metal leaving a 3-4 mil angular anchor profile. All areas were wiped down with M.E.K., a clean, dry solvent.

PES 180 Structural Adhesive is a metal filled polymeric with an extended working life. We applied this to both the bottom of the barrel and steel repair plates. A vacuum was applied to the chiller barrel to help pull PES 180 into any pin holes and sealing them. Using wooden shims and industrial nylon ratcheting straps, we pulled repair plates tight and sealed all leaks. Once this hardened, we removed straps, performed some hand sanding and applied a second coat of PES 180 along with fiberglass reinforcing mesh fabric to reinforce any seams.

Photo Gallery of the Chiller Repair

Replacement of this chiller would have cost approximately $250,000-$300,000 to remove and replace this essential piece of HVAC cooling equipment. Our PES repair procedure resulted in saving the end user hundreds of thousands of crucial expense dollars.