Expansion joints are extremely important because they allow for the accommodations of temperature changes. Changes in temperature can cause problems or destruction. There are a few different types of expansion joints, this article will discuss flue duct expansion joints specifically.

Having the right flue duct expansion is extremely important to prevent leakage, lessen noise and vibrations, maintain operation and safety stands and reduce the chance of failure. PES Solutions uses HOLZ expansion joints designed to your specifications to ensure high quality for industrial ductwork systems.

Ideal Applications for HOLZ Flue Duct Expansion Joints:

- Scrubber

- Precipitator

- Baghouse

- Stack hot air or flue gas ducts

- Steam boiler systems

- Gas turbine exhausts

- Industrial furnace & chimney construction

- Refuse incinerators

- Ventilation and aeration systems

- Emissions control

- Paint and power coating booths

- Welding booths

- Environmental systems

- HVAC and air handling systems

- Furnace/Boiler exhaust

- Fan connectors

- Flex element for FRP piping

- FGD systems

We can meet all your flue duct expansion joint repair and replacement needs. Contact PES Solutions today for more information!

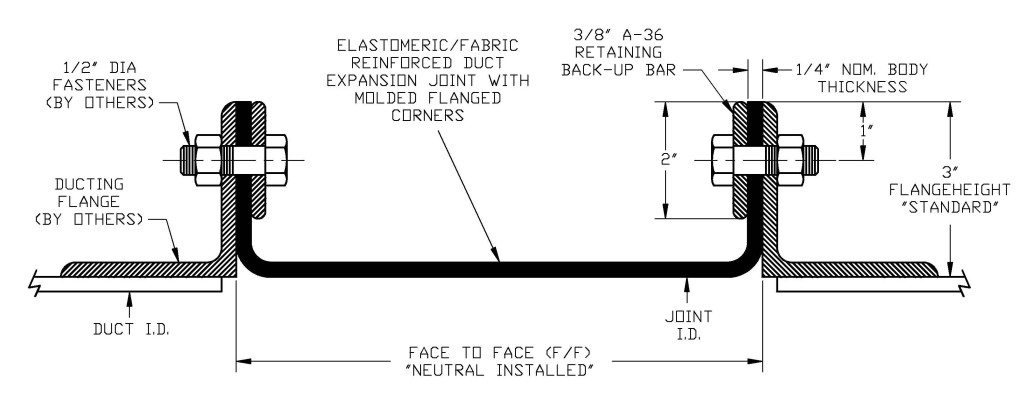

Standard Movement Flue Duct Expansion Joint

Built for standard or normal movement, the HOLZ 942 U-Design Flue Duct Expansion joint is equipped for applications requiring standard movement, maximum noise, vibration and sound absorption, allowing superior protection to duct systems, flanges and equipment housing.

Typical Installation Arrangement

Maximum Movement Capabilities (In Inches)

Maximum Movement Capabilities (In Inches)

Movement shown at face-to-face

Lateral Offset figures are based on the assumption that all lateral movement occurs prior to compression movements. In practice, movements may occur simultaneously thus the allowable lateral offset may increase or decrease.

Extension may be increased or decreased by pre-compression during installation. However, the amount of pre-compression will correspondingly reduce the compression ratings.

Pressure/Vacuum Ratings

For constant vacuum, a set-back may be required to ensure the joint is not in the media stream.

Product Weight

Add 6 inches to the face-to-face dimension for calculating the square footage. Retaining Bars: 3/8″ X 2″, A-36 Carbon Steel.

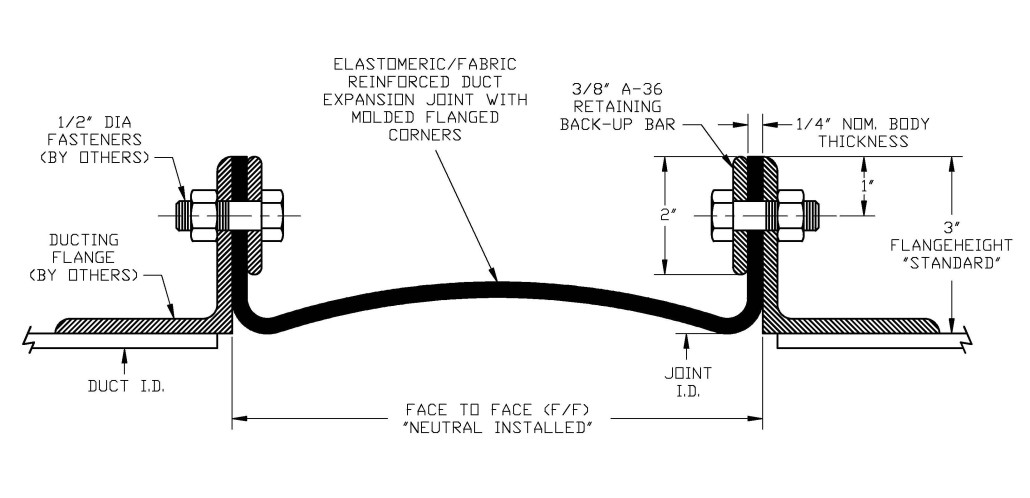

Maximum Movement Flue Duct Expansion Joint

Built for maximum movement, the HOLZ 945 W-Design Flue Duct Expansion Joint is ideal for applications in a scrubber, precipitator, baghouse and stack, hot air or flue gas ducts. It offers superior axial and lateral movement capabilities without pre-compression or pre-extension. The compound curve molded corners ensures that the reinforcing material is not pre-stressed at the neutral installed face dimension.

Typical Installation Arrangement

Maximum Movement Capabilities (In Inches)

Maximum Movement Capabilities (In Inches)

Movement shown at face-to-face

Lateral Offset figures are based on the assumption that all lateral movement occurs prior to compression movements. In practices, movements may occur simultaneously thus the allowable lateral offset may increase or decrease.

Extension may be increased or decreased by pre-compression during installation. However, the amount of pre-compression will correspondingly reduce the compression ratings.

Pressure/Vacuum Ratings

For constant vacuum, a set-back may be required to ensure the joint is not in the media stream.

Product Weight

Add 7 inches to the face-to-face dimension for calculating the square footage. Retaining Bars: 3/8″ X 2″, A-36 Carbon Steel.

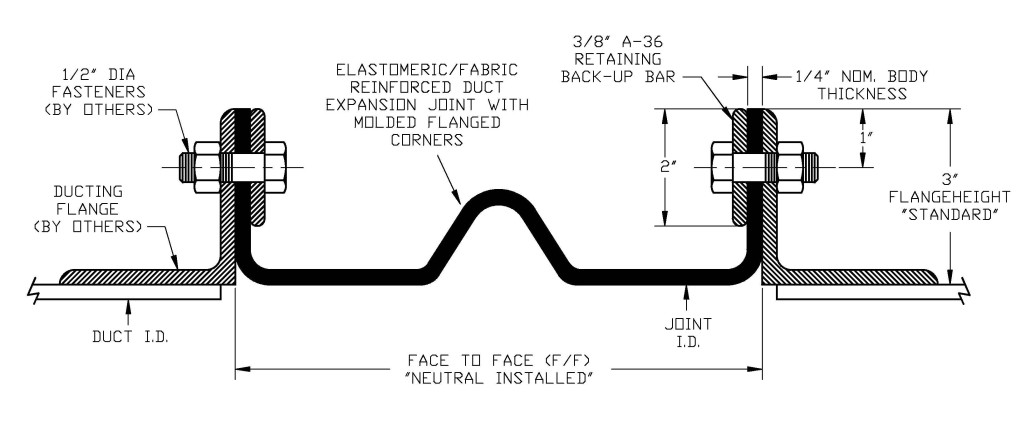

Ultra-High Movement Flue Duct Expansion Joint

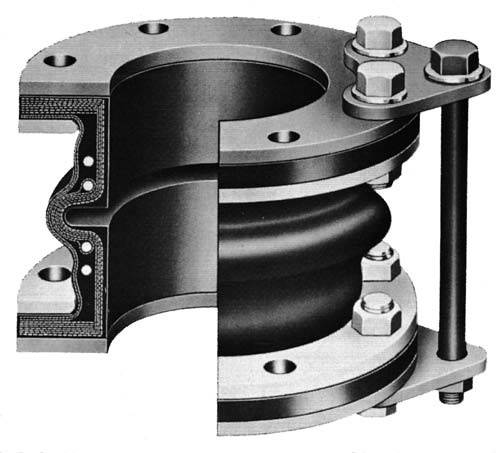

Designed for ultra-high movements in short face-to-face applications, the HOLZ 952 Arch-Design Flue Duct Expansion Joint is constructed with a large, high “V” shaped arch which allows very high axial movement while exerting very low forces on the ductwork, duct flanges and equipment. It’s primarily used for positive pressure clean systems as it has ultra-high axial compression and extension movement.

Typical Installation Arrangement

Maximum Movement Capabilities (In Inches)

Maximum Movement Capabilities (In Inches)

Movement shown at face-to-face

Lateral Offset figures are based on the assumption that all lateral movement occurs prior to compression movements. In practice, movements may occur simultaneously thus the allowable lateral offset may increase or decrease.

Extension may be increased or decreased by pre-compression during installation. However, the amount of pre-compression will correspondingly reduce the compression rates.

Pressure/Vacuum Ratings

For constant vacuum, a set-back may be required to ensure the joint is not in the media stream.

Product Weight

Add 8 inches to the face-to-face dimension for calculating the square footage. Retaining Bars: 3/8″ X 2″, A-36 Carbon Steel.

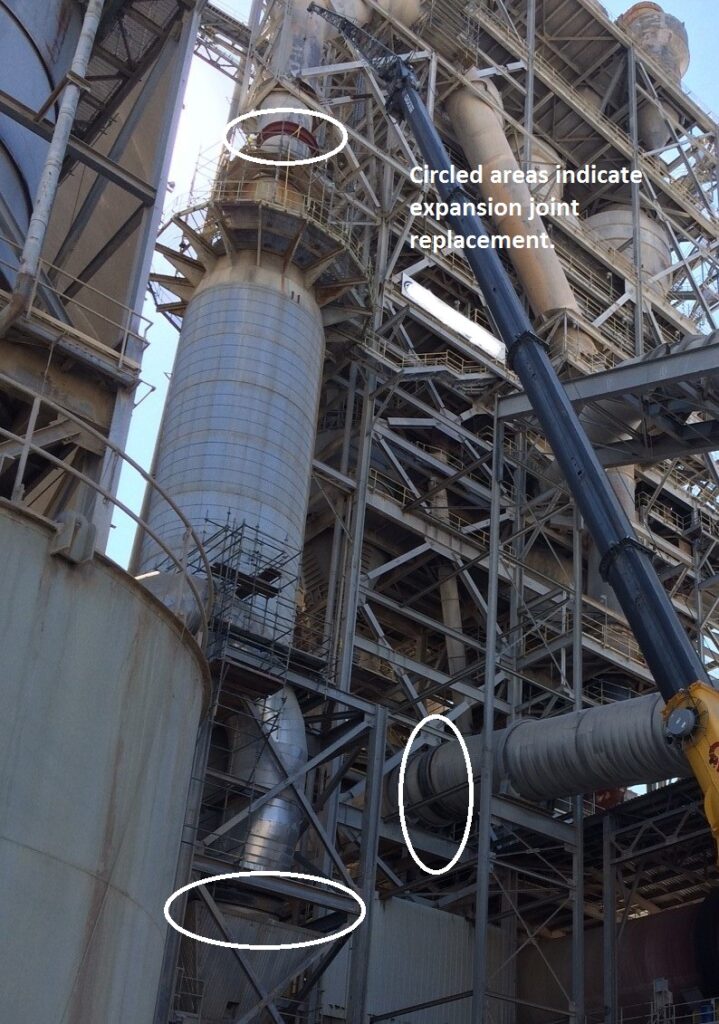

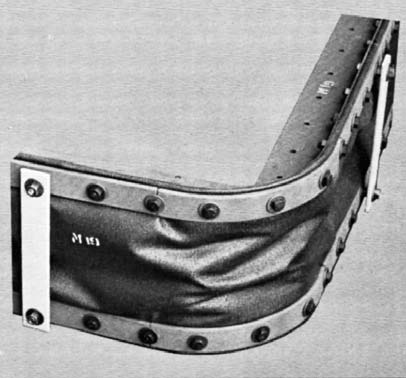

Flue Duct Expansion Joint Repairs Done by PES Solutions

New joints and frames for a repair done by us:

HOLZ Pressure Joint and Duct EJ:

If you need your expansion joint replaced or repaired PES Solutions has you covered! Contact us today with the link below for more information!