Polymeric Engineered Solutions PES 101 Power Metal Paste is a two component solvent free epoxy metal repair compound. The product has been designed for use on a wide range of metallic, and non-metallic surfaces, and once cured is readily machinable. PES 101 Power Metal Paste has been replacing products like Belzona 1111 Super Metal on warehouse shelves for years. We will discuss the process of applying PES 101 Power Metal Paste for shaft repair.

PES 101 Power Metal Paste for Shaft Repair

PES 101 high qualities and better price make it the best choice in an all-around general purpose repair compound used to stop leaks in tanks, repair bearing fits, key-ways, and splines on shafts. It will rebuild eroded areas, flange faces, and cracks on pumps. Many heat exchanger tube sheets have been repaired and rebuilt using PES 101 to seal around tubes for leaks, to rebuild from bi-metallic corrosion caused from dissimilar metals, repair-rebuild end caps, water boxes, and channels.

Additionally, PES 101 has been used for years in automobile repair such as cracks on manifolds, engine blocks, stripped threads on oil pans, repair of bearing-bushing fits and much more. PES 101 is used to repair scored hydraulic rams, fill gaps and can be used as an adhesive to join many dissimilar materials.

Shaft Repairs – Machined

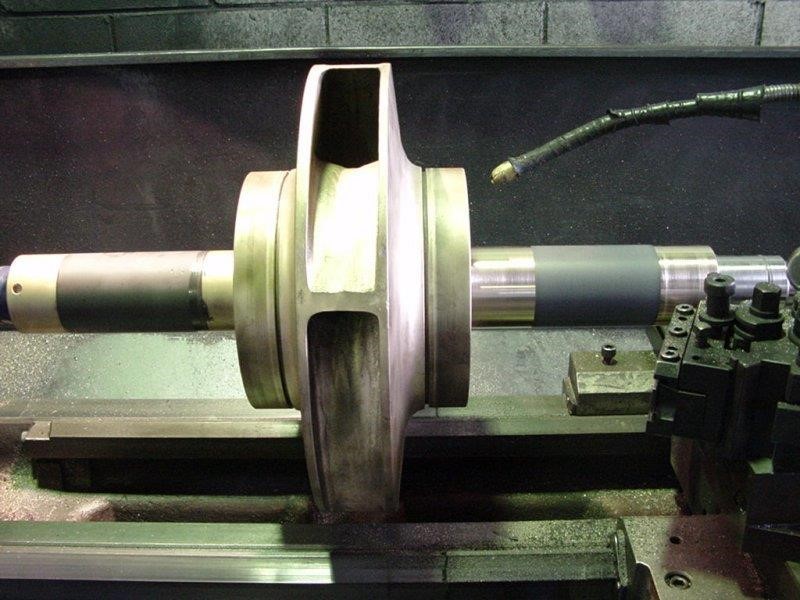

PES 101 Power Metal is applied while the part is in the chuck. After it sets up (about 2 hours @ 68°F), it is machined back to size.

Shaft Repairs – Using the Former (split sleeve) Technique

Shaft is damaged, disassembly is difficult or impractical. Repair in place is attractive. Remove old bearing and other obstructions. Prep the shaft with grinders. Leave surface as rough as possible.

Machine a split sleeve (can be made from any right material). The I/D of the sleeve is to be the same as the O/D of the shaft. 1/8″ weep holes are drilled in the sleeve every 3-4 inches. Release agent is applied to the sleeve. PES 101 Power Metal is applied to both the shaft and the sleeve. The sleeve is clamped in place.

Once the PES 101 Power Metal material has cured (2 to 4 hours @ 68°F), the sleeve is removed. Parting lines and nubs from the weep holes are cleaned up with emery cloth and the shaft is ready for reassembly.

Advantages to Polymeric Repair Systems

- No heat distortion, stress or metallurgical changes to substrate material.

- Our materials are based on resilient resin systems which allow the same product to be used on multiple substrates. This also makes our materials able to withstand vibration, impact and thermal movement better than other systems.

- Effective on any substrate (aluminum, cast iron, stainless…)

- No special equipment required.

- Easy application

- Can be done in place

- Minimal downtime

- Cost effective

For more information on our PES 101 Power Metal Paste, contact PES using the link below!

I have a crack in the block on my boat motor about 3 inches long. Do you think the 101 we’ll work and hold up. Thanks Tim Heslin

Hello,

We’re sorry for the late response to this, but to answer your question, our PES 101 can be used to repair your boat motor. It can also be used to repair fiber glass or metal boat hulls.

Feel free to reach out to us if you have any more questions.