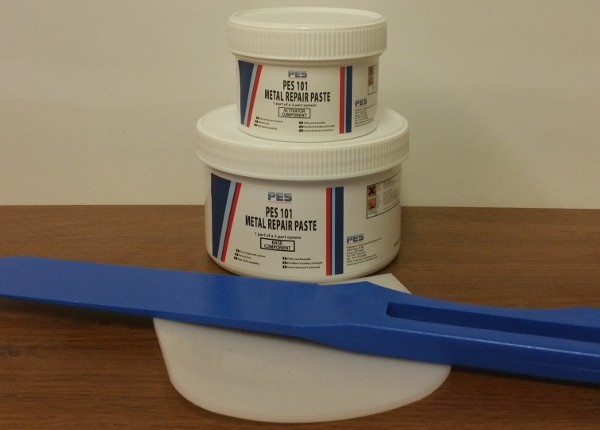

PES 101 Power Metal Repair Paste is a two component solvent free epoxy metal repair compound. The product has been designed for use on a wide range of metallic surfaces and once cured is readily machinable. Suitable for emergency repairs or part of planned maintenance to equipment such as worn or damaged pump shafts, cracked pump or valve casings, scored hydraulic rams, worn bearing housings, damaged flanges, leaking tank seams, worn keyways and cracked engine blocks.

Shaft Repair

Machined

PES 101 Power Metal is applied while the part is in the chuck. After it sets up (about 2 hours) it is machined back to size.

Using the Former (split sleeve) Technique

When the shaft is damaged, disassembly can be difficult or impractical. Repairing the shaft in place is attractive. Simply remove the old bearing and other obstructions. Then, prepare the shaft with grinders and leave the surface as rough as possible.

Machine a split sleeve (can be made from any rigid material). The I/D of the sleeve is to be the same as the O/D of the shaft. Weep holes of 1/8″ are drilled in the sleeve every 3-4 inches. The release agent is applied to to the sleeve. PES 101 Power Metal is applied to both the shaft and sleeve, and the sleeve is clamped in place.

Once the PES 101 Power Metal material has cured (2 to 4 hours), the sleeve is removed. Parting lines and nubs from the weep holes are cleaned up with emery cloth and the shaft is ready for reassembly.

Advantages to Polymeric Repair Systems

- No heat distortion, stress or metallurgical changes to substrate material.

- Our materials are based on resilient resin systems which allow the same product to be used on multiple substrates. This also makes our materials able to withstand vibration, impact and thermal movement better than other systems.

- Effective on any substrate (aluminum, cast iron, stainless, etc.)

- No special equipment required.

- Easy application

- Can be done in place

- Minimal downtime

- Cost effective

Mechanical Repairs

PES Metal Repair Systems are ideal for rebuilding and resurfacing worn or badly damaged mechanical equipment and components. The materials are based on the latest two pack solvent free epoxy technology.

The product range includes various grades to suit the numerous repairs faced by engineers and can be easily machined down to fine tolerances for close fitting components these include paste, fluid, fast curing and extended working life.

Typical Repairs

Typical repairs include the following:

- Leaking tank seams

- Sloppy keyways

- Scored hydraulic rams

- Cracked engine blocks

- Worn bearing housings

- Plate Bonding

- Worn drive shafts

- Holed pump casings

Features

Features of the product range include the following:

- Simple and easy to mix

- Solvent free

- No shrinkage or slumping

- Easily machined down to a smooth finish

- Good chemical resistance

- Capable of resisting temperatures up to 356°F (Dry)

Benefits

- Allow quick and effective repairs to mechanical components

- Reduced downtime of essential equipment

- Cost effective solution to a wide range of maintenance problems

- Reduction in life cycle of key operating plant

One of the biggest benefits of PES 101 Power Metal Repair Paste is the lower price. Often times, this product is overpriced but PES-Solutions provides this long-lasting product at a lower price to better assist our customers and their specific needs. We offer a variety of package options as well, including 500GM, 1KG, 2KG, 3KG and 30KG PES 101 Power Metal Repair Paste.

Specifically designed for metallic surface, this product is great for emergency repairs or part of planned maintenance equipment such as worn or damaged pump shafts, cracked pump or valve casings, scored hydraulic rams, worn bearings housings, damaged flanges, leaking tank seams and cracked engine blocks.

Dear Sir,

Please forward Your authorized dealer details in india for En-8 Klin Shaft (230 to 280 dia) rebuild purpose

Hello,

You can contact Resimac for this information at info.resimac.co.uk.

Hi

Thanks for the blogs about the metal solder and its process. Keep rocking and very useful . Please do share more articles.

Hey there! We’re happy you enjoyed the article. Keep an eye out for more from us!

Take care.