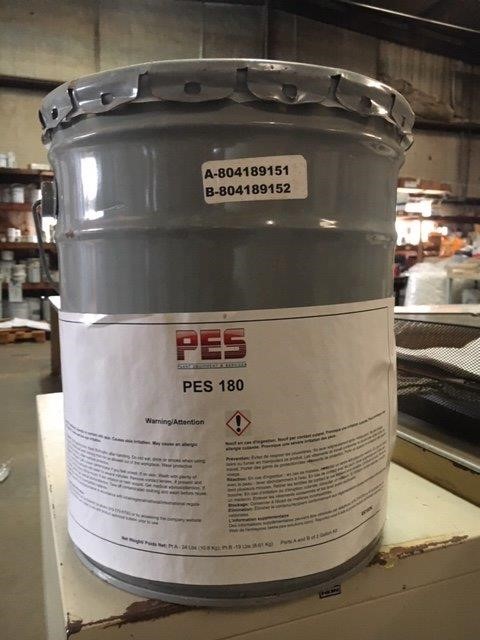

PES 180 Structural Adhesive

Typical Application

- Body Coat – PES 180 @ 1/8″ thickness

Performance data

- Comprehensive Strength – ASTM C-579 – 11,000 psi

- Tensile Strength – ASTM C-307 – 2,400 psi

- Bond Strength – ASTM C-4541 – >1,000 psi

- Hardness (Shore D) – ASTM D-2246 – 87

- Density – ASTM C-905 – 165 pcf (2.64 gm/cm3)

- Heat Resistance – 300°F

Storage & Installation

- Storage Environment – Dry area, indoor: 65-80°F

- Application Temperature, ambient – 40-95°F

- Application Temperature, substrate – 40-95°F

- Shelf Life – 24 months

- Pot Life, @ 77°F – 40 minutes

- Tack Free Time, @ 77°F – 2.5 hours

- Light Movement @ 77°F – 4 hours

- Full Loading @ 77°F – 2 days

- Contact with Chemicals @ 77°F – 3 days

Material cures more slowly at cooler temperatures, and working time will be substantially reduced at higher temperatures. In hot weather, material should be cooled to 65°F to 80°F prior to mixing and application to improve workability and avoid shortened pot life. The data shown above reflects typical results based on laboratory testing under controlled conditions. Reasonable variations from the data shown above may result.

Considerations & Limitations

- Do not thin with solvents unless advised to do so by PES.

- Prepare substrate according to “Surface Preparation” portion of this document.

- Always use protective clothing, gloves and goggles consistent with OSHA regulations during use. Avoid eye and skin contact. Do not ingest or inhale. Refer to Material Safety Data Sheet for detailed safety precautions.

- For industrial/commercial use. Installation by trained personnel only.

- Do not apply when the temperature is below 40°F (5°C) or the relative humidity is above 85%.

- Do not apply when there is moisture on the metal surface or is likely to be deposited by subsequent condensation.

- Do not apply when the working environment is likely to be contaminated by oil/grease from adjacent equipment or smoke from kerosene heaters or tobacco smoking.

Surface Preparation

This product can be applied to substrate(s) that have been prepared according to the following Surface Preparation Guidelines:

Apply only to blast cleaned surfaces.

- Clean up loose contamination and degrease with a rag soaked in an effective cleaner, e.g. methyl ethyl ketone (MEK), which does not leave a residue.

- Use only an angular abrasive to give a minimum depth of profile of 3 mils.

- Blast-clean the metal surface to achieve near white finish SSPC SP 10.

- After blasting, metal surfaces should be coated before any possible oxidation.

Metal must have <3µg/cm2 chloride and <5µg/cm2 sulfate contamination.

Installation Steps

- Mixing: Pre-blend Part A and Part B before beginning. Measure equal volumes of Part A and Part B. Place Part B into Part A and mix together using a mechanical mixer, such as a Jiffy mixer, scrape the sides and bottom of the container and mix an additional minute to ensure material is homogeneous. Warning: Improperly mixed material will not cure properly.

- Application: Apply PES 180 onto prepared surface with a plastic applicator, spatula, or trowel blade. Press down firmly to remove entrapped air and insure maximum bonding to the surface. If necessary, additional layers should be applied when the first layer is still soft, within 2 hours at 77°F. If the over-coating time is exceeded, brush blast the cured material before any further application.

- Cleaning: Clean tools with a non-flammable and low-evaporating cleaner. Always wear gloves when using this product. Wash hands, arms and face with warm soapy water.