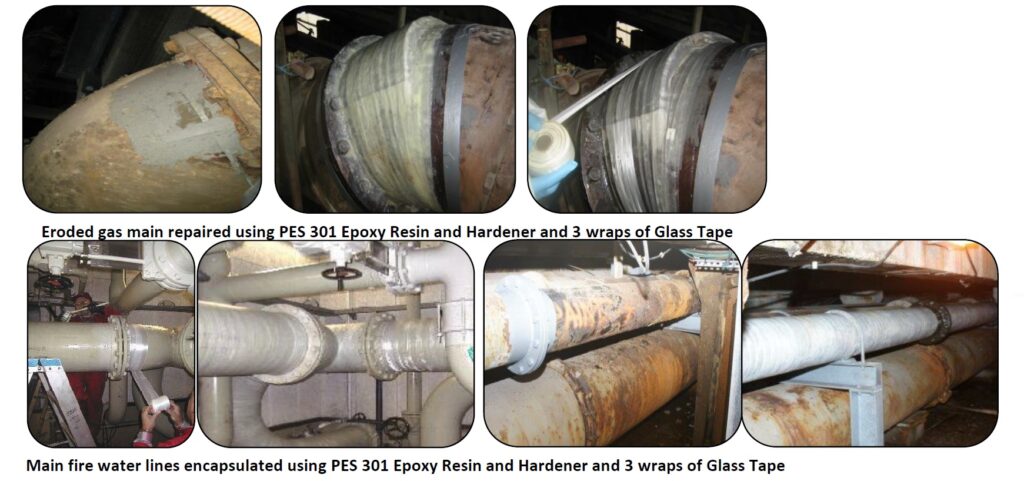

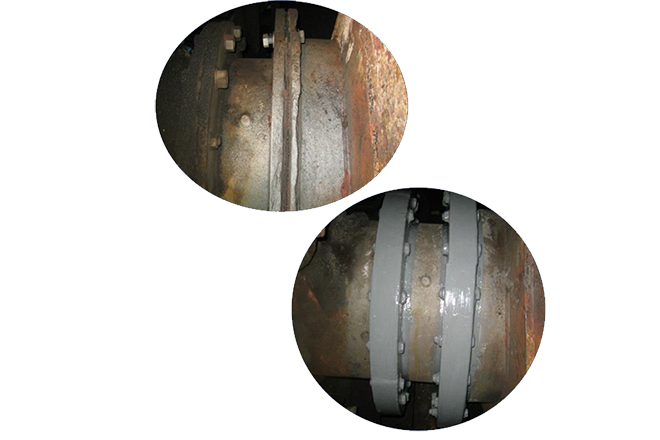

PES 301 Epoxy Resin and Hardener is a two component thixotropic solvent free epoxy material for injection applications, bonding of dissimilar materials, and for use in conjunction with a range of tapes and fabrics to produce high strength composite repairs. The product can be applied to manually prepared surfaces and is ideal for encapsulating problem pipework ranging from 1″-36″ diameter. Once cured, the system can resist up to 300 psi pressure. For injection applications the material can be pumped into voids up to 15mm in depth.

PES 301 Epoxy Resin and Hardener

Main Characteristics –

- Two component

- Solvent free epoxy

- Usable life 25 minutes 68°F (20°C)

- Touch dry 90 mins 68°F (20°C)

- Full cure 5 days 68°F (20°C)

- Up to 300psi pressure tolerance 3 x Wrap of glass tape

- Applied by brush or applicator tool

- Available in 1kg, 3kg, 30kg pack sizes

- Tolerant of less than ideal surface preparation

Mechanical Properties –

Adhesion

Tensile Shear to ASTM D1002 – 2100psi, (148kg/cm²)

Compressive strength

Tested to ASTM D 695 – 14,700psi (1034kg/cm²)

Corrosion Resistance

Tested to ASTM B117 – Minimum 5000 hours

Flexural Strength

Tested to ASTM D790 – 13,000psi (912kg/cm²)

Heat Resistance

Suitable for water immersion up to 158°F (70°C) and intermittent contact with steam up to 248°F (120°C) (when used with glass tape, dry heat resistance up to 302°F (150°C).

For further information, contact PES using the link below!

Thanks for the introduction,it`s very useful for me.