Protecting both the interior and exterior of the tower helps prevent corrosion and leaks, which will extend the life of your equipment. PES-Solutions provides coatings to prevent leaks in cooling towers, as well as corrosion and rusting.

Interior and Exterior Coatings to Prevent Leaks in Cooling Towers from PES-Solutions

If the interior of your cooling tower is corroding, rusting or leaking, we can apply an epoxy coating to seal and eliminate all leaks.

Alternatively, we can also apply an epoxy coating to your cooling tower exterior to eliminate corrosion, rust and leaks.

Benefits of PES-Solutions Epoxy Coatings for Cooling Towers

In addition to preventing leaks in cooling tower systems, our coatings can help protect and provide corrosion resistance. Our cooling tower epoxy coatings help bridge over holes, seams and cracks. We can also apply PES coatings in hot and cold water basin, which provides an impermeable and corrosion resistant barrier to cooling water.

Strong Adhesion Strength for Multiple Substrates

PES epoxy coatings have a strong adhesion to substrates typically found in cooling towers, including galvanized steel, stainless steel, fiberglass, concrete and previous coating surfaces.

Quick and Easy Coating Application

Our epoxy coatings are quick and easy to apply, so that your cooling tower is running smoothly in no time. Our coatings can make maintenance of cooling towers easier. Therefore, there’s less maintenance work for you.

PES-Solutions Cooling Tower Epoxy Coating Application Services

In a recent project we did, our customer had a concrete cooling tower that had been leaking for over 20 years as a result of cracks in the concrete. The customer had the tower coated by another contractor previously, but it still leaked. So, they hired another contractor to install thick Polyethylene liner, which didn’t work well either.

They hired PES-Solutions two years ago, and we just completed another cell in their 4 cell cooling tower. The steps have been the same each year, including surface prep and detailing cracks, corners and 90° transitions. However, this year we used our XM50 plural spray rig to spray the coatings instead of our standard 45-1, or 68-1 spray equipment.

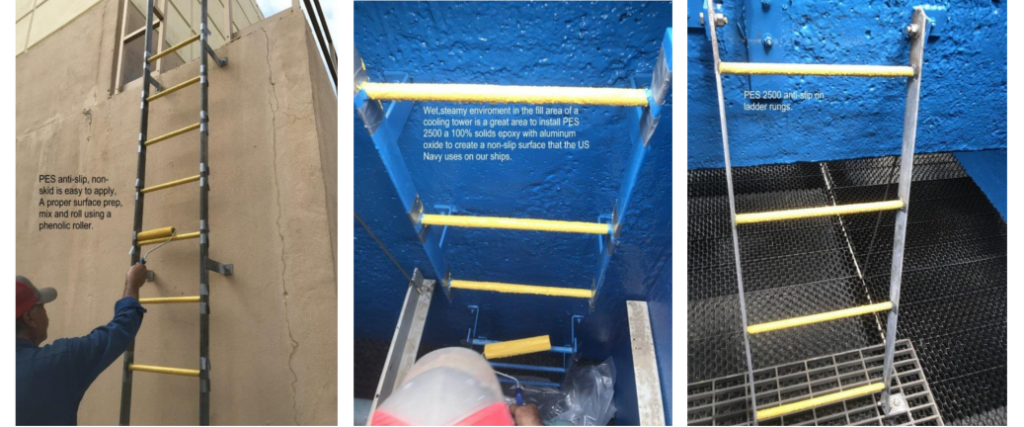

The XM50 mixes the epoxies inside the spray hoses just before the spray gun, instead of a mixing bucket at the pump. This saves many valuable pot life minutes. Another difference this year is the addition of our Anti-slip coating PES-2500 Safety yellow to the ladder rungs inside of the cooling tower.

Here are the before pictures of this project:

Our Cooling Tower Epoxy Application Process

Step 1: Identify Cracks and Corners

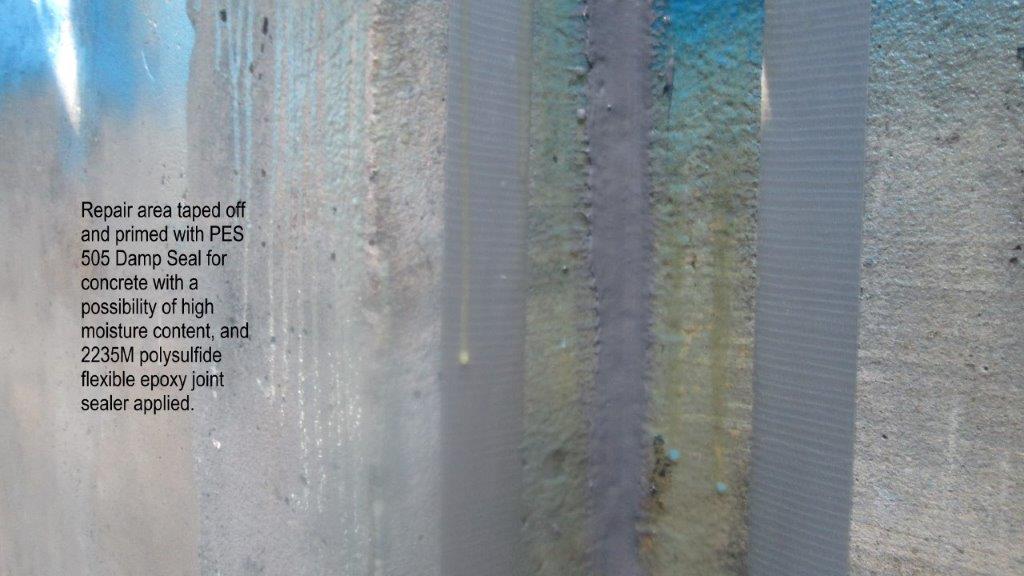

The repair area is taped off and primed with PES 505 Damp Seal for concrete with a possibility of high moisture content. Also, 2235M polysulfide flexible epoxy joint sealer is applied.

Step 2: Apply Heavy Coating of Flexible Membrane Epoxy

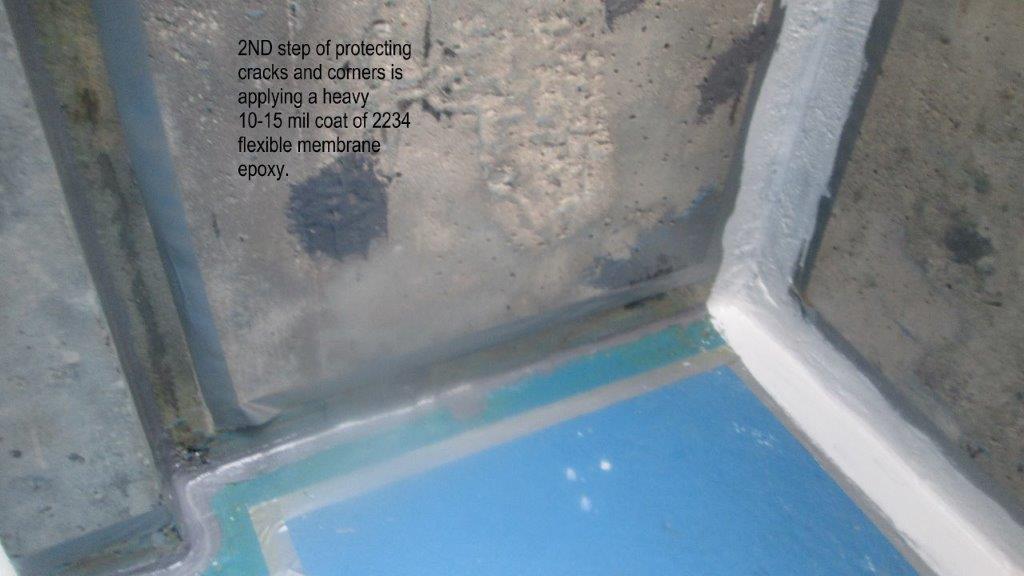

Next, we apply a heavy 10-15 mil coat of 2234 flexible membrane epoxy.

Step 3: Repair Cracks and Corners with a Belt & Suspenders Approach

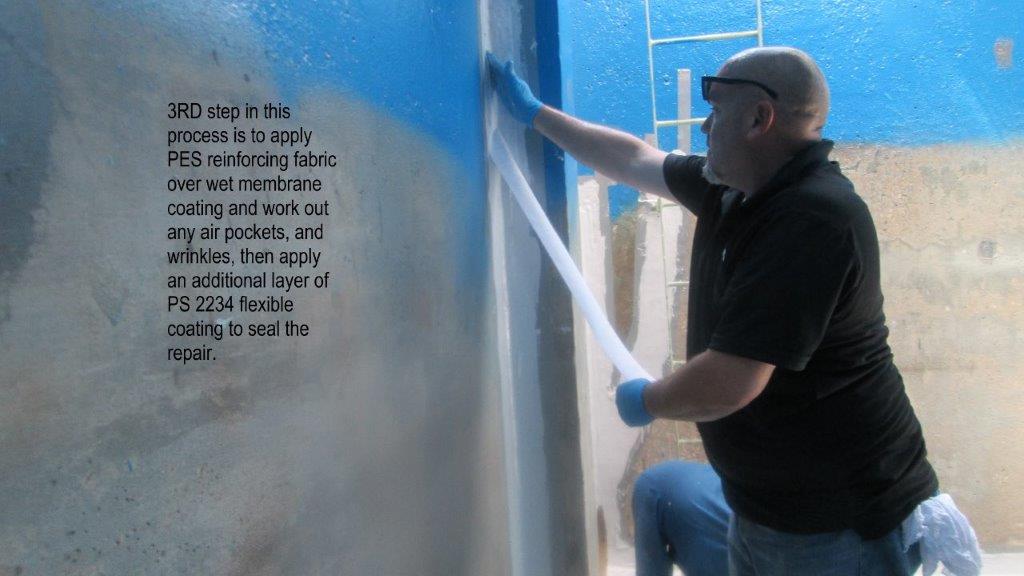

The third step in our process is applying PES reinforcing fabric over wet membrane coating and work out any air pockets and wrinkles. Then, we apply an additional layer of PES 2234 flexible coating to seal the repair.

Step 4: 90° Transition

The 90° transition requires detailing the Plenum of the cooling tower.

Step 5: XM50 Plural Spray Rig and PES 501 CRSG Blue

Once PES 505 has been applied, we then apply 2 coats of PES 501 CRSG using our plural spray rig at 20-30 mils per coat.

Step 6: Anti-Slip Coating Application

If needed, we can also apply PES anti-slip, non-skid to your cooling tower.

For more information on our cooling tower coatings, or to schedule you service today, don’t hesitate to contact us with the link below!

Epoxy coating is the most effective coating among the other coating.But did not know that it could help prevent leaks in cooling towers.Thanks for sharing this article.

Cooling tower concrete joints are leaking, looking for your support to advise us best sealant.

Concrete wall joints leak, advise us best sealant

Hello,

The best sealant for concrete repair is PES 575. Let us know if you’d like more information for your concrete repair needs.