Making a repair to your heat exchanger with a Polymeric Engineered Solution can prove to be extremely durable and cost effective.

Repairing Your Heat Exchanger with Polymeric Engineered Solution Products

PES 201 Ceramic Repair Paste

PES 201 Ceramic Repair Paste is a two component solvent free epoxy metal repair compound. The product has been designed for use on a wide range of metallic surfaces subject to abrasion and impact. It is suitable for emergency for repairs or part planned maintenance to equipment such as worn impellers, damaged valves, eroded separator housings, damaged pump casings, eroded pipe work, propellers, bow thrusters, rudders, corroded water boxes and eroded end plates and tube sheets.

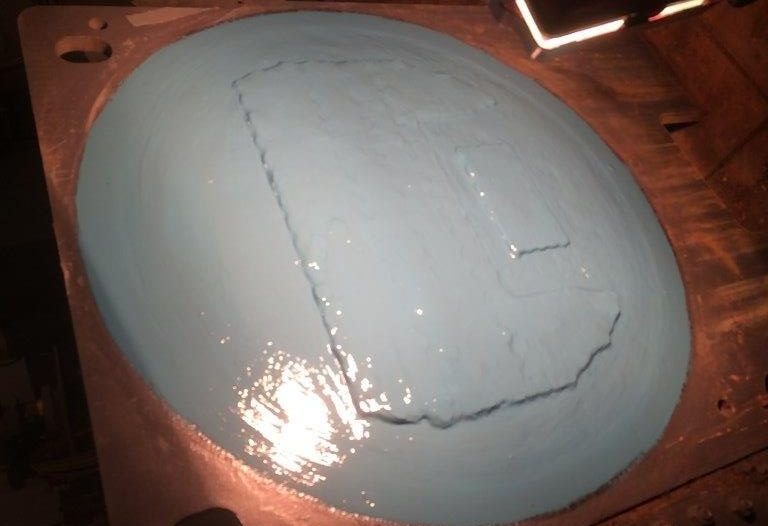

Examples of eroded metal being rebuilt with PES 201 on the end bells:

PES 202 Ceramic Repair Fluid

PES 202 Ceramic Repair Fluid is an erosion-corrosion resistant coating for use principally in fluid flow situations. The material can be applied directly to abrasive blasted steel or to surfaces previously rebuilt with PES 101 Power Metal Paste or PES 201 Ceramic Repair Paste. It is suitable for the coating of equipment such as impellers, pump casings, valves, heat exchanger end plates, water boxes, separator housings, pipes, propellers, kort nozzles and rudders.

PES 203 Super Flow Ceramic Repair Fluid

PES 203 Super Flow Ceramic Repair Fluid is an erosion-corrosion resistant coating used principally in fluid flow situations for improving flow efficiency. The material can be applied directly to abrasive blasted steel or to surfaces previously rebuilt with PES 101 Power Metal Paste or 201 Ceramic Repair Paste. It is suitable for the coating of equipment such as pump cases and impellers, valves, pipes, propellers, rudders, jet tubes, kort nozzles and more.

Example of end bells after 2 coats of PES 202 and final coat of PES 203:

Do you need to repair a crack on your heat exchanger? PES-Solutions has the product for you! Don’t hesitate to contact us with the link below for more information!