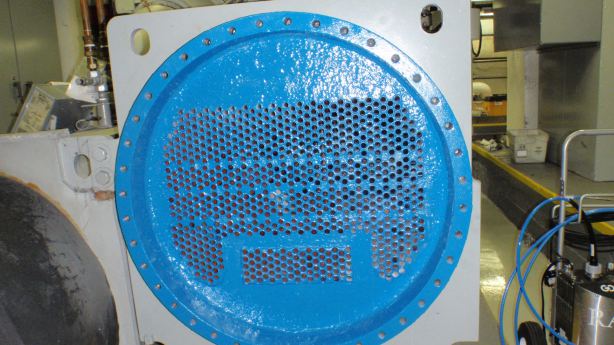

Chiller Repairs and Common Problems

Proper operation and maintenance of the building chillers should be a high priority in any facility energy management program. Inefficient or ineffective operation or maintenance can result in higher energy costs, lower system performance and reliability, and decreased equipment life. We will discuss common chiller problems and chiller repair solutions we offer. Common Problems with Chillers…

Proper operation and maintenance of the building chillers should be a high priority in any facility energy management program. Inefficient or ineffective operation or maintenance can result in higher energy costs, lower system performance and reliability, and decreased equipment life. We will discuss common chiller problems and chiller repair solutions we…

View moreCooling towers are used to cool down water that goes through chillers and other heat exchanger equipment. Ultimately, it is a heat rejection device which utilizes the evaporative cooling process to transfer waste heat from the atmosphere. Not having your cooling tower properly maintained can lead to leaks and standing water which…

View moreWhen you are planning an epoxy coating project, it is important to choose the right epoxy coating that best suits your needs. Epoxy coatings are available in a variety of thickness and styles that can be customized to meet your requirements for durability, functionality and aesthetics. PES Solutions can help…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Secondary Containment Liners…

View moreAre you confused about the federal secondary containment regulations? We know how mind-numbing this stuff can be. This is why we are going to break it down for you in this article. These are the top 5 main points we think it is consider under the EPA's hazardous waste storage…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Corrosive Environments The…

View moreExpansion joints are extremely important because they allow for the accommodations of temperature changes. Changes in temperature can cause problems or destruction. This article will discuss some of the basics of expansion joints. Types of Expansion Joints Types of expansion joints include: Piping Expansion Joints Flue Duct Expansion Joints High…

View moreIf you have heavy duty pails, drums or totes storing materials at your facility then you should strongly consider secondary containment. A secondary containment serves as reinforcement by means of an outer wall or secondary barrier. Theses containers main function is to prevent contamination and ensure safety. Types of Secondary…

View morePES 205 Ceramic HT Fluid PES 205 Ceramic HT Fluid is a two component solvent free epoxy novolac coating designed for high temperature immersion conditions. The product, once cured, can withstand continuous immersion conditions up to 266ºF (130°C) and can upgrade the performance of conventional materials of construction. The material…

View moreWhat is the PES 108 Pipe Leak System? The PES 108 Pipe Leak System repairs the cracks and leaks in many metals and plastic pipes such as Carbon steel, aluminum, galvanized; PVC, CPVC, PVDF, stainless, polyethylene, polypropylene and fiberglass pipes. It also reinforces the joints and forms an anti-corrosion coating….

View more