PES 101 Power Metal Repair Paste

Is a two-component solvent-free epoxy metal repair compound designed to fill surface erosion & corrosion on metallic surfaces. Typical Applications 101 power metal paste notes Plant Equipment & Services, Inc. (979) 779-8700 pes1@pes-solutions.com

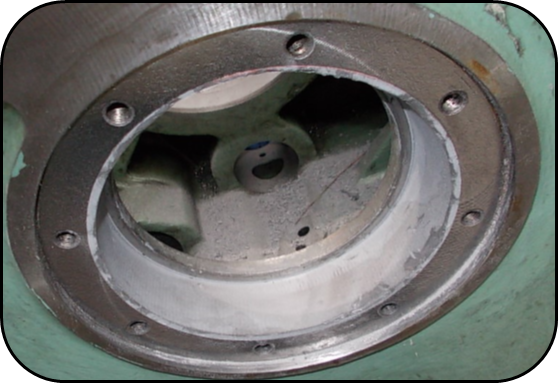

Is a two-component solvent-free epoxy metal repair compound designed to fill surface erosion & corrosion on metallic surfaces. Apply to mechanically & abrasive blast-cleaned surfaces High mechanical adhesion to metal substrates Apply at thicknesses up to 1” Typical Applications worn or damaged pump shafts cracked pump or valve casings scored…

View morePolymeric Engineered Solutions has a wide range of metal repair products capable of resurfacing damage or worn metallic surfaces. Below is a table for our Typical Applications. 101102103104105106107Base plate – cracked¤ ¤ ¤¤Bearing housing – rebuild¤ ¤Bearing support – rebuild¤ ¤Bow thrusters – rebuild¤ ¤Chutes – rebuild¤ ¤¤Engine block– crack¤ ¤ ¤¤Engine block – rebuild¤ ¤Evaporators – rebuild¤ ¤Flange repair¤ ¤¤ ¤¤Heat…

View morePolymeric Engineered Solutions has a wide range of metal repair products capable of resurfacing damage or worn metallic surfaces. Below is a table of our Metal Repair Products – Product Specifications. 101102103104105106107Compressive strength15,300psi15,300psi12,000psi2630psi12,000psi2630psi11,900psiTested to ASTM D 6951075kg/ cm²1075kg/ cm²843kg/ cm²185kg/ cm²843kg/ cm²185kg/ cm²839kg/ cm²Corrosion Resistance5000 hours5000 hoursn/a5000 hoursn/a5000 hours5000 hoursTested…

View morePolymeric Engineered Solutions has a wide range of metal repair products capable of resurfacing damage or worn metallic surfaces. Below is a table for our Metal Repair Products and Product Selector Guide. 101102103104105106107Product CharacteristicsEpoxy¤¤¤¤¤¤¤ Polyurethane Solvent Free¤¤¤¤¤¤¤ Solvent Based Paste Grade¤ ¤¤ Fluid Grade ¤ ¤ Putty Grade ¤ ¤ Machinable¤¤¤¤¤¤¤CuringFast Cure <45mins ¤¤¤¤ Standard Cure <2hrs¤¤ Extended Cure <4hrs ¤Wet Film Thickness<40 mil build ¤ 1/32-7/64” ¤ Up to…

View moreThe PES-Metal ceramic enhanced product range is based on the latest solvent free epoxy technology and is ideally suited to rebuilding and resurfacing equipment and components in a fluid flow environment. The product range has been designed to be easy to apply, offer good chemical resistance and excellent impact and…

View moreWhen you are planning an epoxy coating project, it is important to choose the right epoxy coating that best suits your needs. Epoxy coatings are available in a variety of thickness and styles that can be customized to meet your requirements for durability, functionality and aesthetics. PES Solutions can help…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Secondary Containment Liners…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Corrosive Environments The…

View morePES 205 Ceramic HT Fluid PES 205 Ceramic HT Fluid is a two component solvent free epoxy novolac coating designed for high temperature immersion conditions. The product, once cured, can withstand continuous immersion conditions up to 266ºF (130°C) and can upgrade the performance of conventional materials of construction. The material…

View morePES-Chem 501 CRSG and PES-Chem 502 CRXF PES-Chem 502 CRSG and 502 CRXF are high build solvent free epoxy coatings designed for the long term protection of steel and concrete structures against corrosion, abrasion and chemical attack. Operating temperature ranges from -4ºF to 104ºF. The two component product is highly…

View more