With cool weather upon us, now is the time to have maintenance on your building’s chilled water system. If your chiller, condensate pans or cooling tower could use a coating system to protect and preserve your equipment, contact us today! We probably already work for your chill water maintenance provider, Carrier, JCI-York, Daikin-Mcquay, Trane and others. Plant Equipment & Services uses the highest quality of products and offers the best service and warranties compared to anyone else in the industry. We will discuss winter chiller maintenance to ensure your chiller works efficiently all year long.

New monitoring technologies and developments in centrifugal chillers with magnetic has allowed winter chiller maintenance to advance significantly. The industry has been moving toward demand maintenance programs and away from pre-determined scheduled maintenance. This is due to remote monitoring. Here are 10 winter chiller maintenance tips that apply to most chillers to help maintain high efficiency.

Winter Chiller Maintenance for High Efficiency

Keep a Daily Log

The first step toward winter chiller maintenance for an efficiently-run chiller plant is keeping a daily log. This log allows you to build a history of operating conditions including temperatures, pressures, fluid levels and flow rates. With remote monitoring technologies, you can continually check machines rather than monthly or every other month. It also allows you to easily generate trend reports that help to identify maintenance needs before they become an issue.

Keep Tubes Clean for Efficient Heat Transfer

Heat transfer efficiency has the greatest single effect on chiller performance. Therefore, it is fundamental to have clean heat transfer to maintain high efficiency. Contaminants such as minerals, scale, mud, algae and other impurities can cause the increase of thermal resistance. In addition, it can reduce the overall performance. A good indicator of heat transfer efficiency are the approach temperatures. High approach temperatures are key indicators that heat transfer efficiency is decreasing. Make sure to brush and lean condenser tube annually, or per demand maintenance schedule to keep them free of contaminants.

Treat Condenser Water to Prevent Scale, Corrosion

Water treatment is essential to eliminate scale, corrosion and biological growth for all condenser water loops using open cooler sources (such as atmospheric cooling towers). These all lead to fouling in the condensers, thus impeding heat transfer and decreasing tube and piping effectiveness. Inspect chilled water loops once a year or regularly with remote monitoring for general water quality and evidence of corrosion.

Lower Entering Water Temperature

You can improve the chiller’s efficiency by lowering the temperature of the entering condenser. The operator will lower the chilled water set point on some building systems. This is to overcome air handler deficiencies such as dirty coils. Although this cures the symptom, it does not cure the problem. As a result, it makes the chiller work harder for the same net cooling effect.

Keep Chilled Water Flow Rate Between 3 to 12-ft per Second

Changing the water flow rate can affect the chiller’s performance. The chiller efficiency can decrease if there is too low of a flow rate, ultimately leading to laminar flow. Typically, the minimum flow rate is around 3-ft. per second (FPS). If the flow rate is too high, this can lead to vibration, noise and tube erosion. The maximum recommended flow rate is usually around 12 FPS.

Maintain Adequate Refrigerant Charge

The actual amount of cooling a chiller provides is dependent on how much refrigerant it moves through the compressor. It is critical to maintain the proper level of refrigerant for the conditions desired. Refrigerant leaks can decrease efficiency and reliability of the system, as well as air and moisture introduced into the system. Having a lower refrigerant charge will cause the compressor to work harder for less cooling effect.

Prevent Inefficiencies Caused by Non-Condensables

Because their evaporators operate in a vacuum, non-condensables such as air and moisture leak into low pressure chillers. The real efficiency of the chiller can be lowered from the rated performance by as much as 4% at 60% load and 7% at 100% load by non-condensables. Purge units and minimize the effect of non-condensables.

Check Operation of Starters and Motors

Check the safety and sensor calibrations on microprocessor controls (consult manufacturer’s guidelines) for efficient operation of starters and motors. Once this is complete, check electrical connections, wiring and switchgear related to the chiller for hot spots and worn contacts. Test electrical motor windings for insulation resistance to ground and winding-to-winding to prevent insulation faults. Make sure to check the shaft seal of open driver motors for possible refrigerant leaks. In addition, clean the motor cooling air vents to ensure maximum cooling effect.

PES Services

Here at PES we can provide all your chiller corrosion maintenance needs, specifically for winter chiller maintenance. We are the leaders in coating chillers and we also offer the best warranty in the state! The coatings we use include:

- PES 201: a ceramic filled paste that helps build up the tube sheet flush with the end of the tubes, and any irregular surfaces caused by corrosion and erosion.

- PES 202: a ceramic filled brushable coating giving a chemical and abrasion resistant surface.

- PES 203: a ceramic filled brushable fluid that leaves a smoother than polished stainless steel finish.

Chiller Coatings Done by PES:

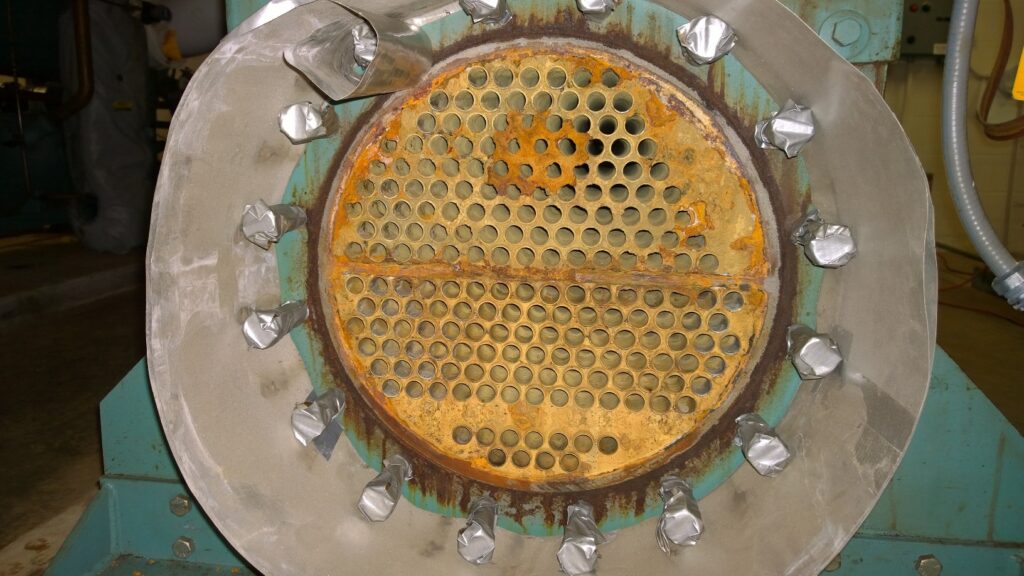

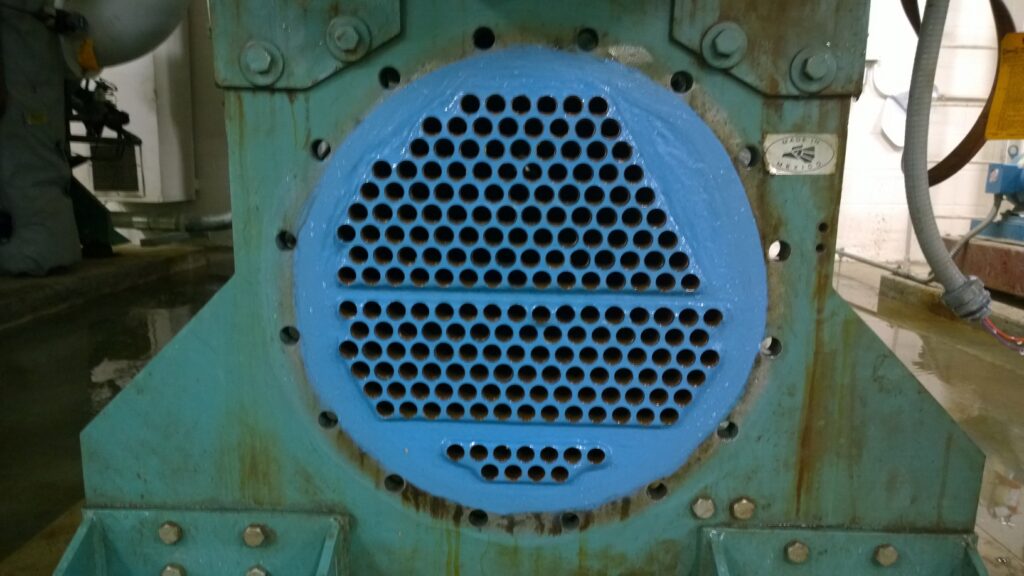

Condenser

Before:

After:

Endbell

Before:

Preparation:

After:

Tubesheet

Before:

After:

We offer the highest quality of products and the best service and warranties for chillers. Contact us with the link below for more information!