Learn more about our power metal and ceramic repairs and services.

Our Process for Power Metal and Ceramic Repairs

Plant Equipment & Services is an HVAC contractor licensed by the state of Texas. We specialize in rebuilding and providing a solution for long term protection of costly corrosion to cooling towers, air handler condensate pans, bearing fits on air handler fan shafts, along with rebuilding and coating chiller tube sheets, water boxes and other associated parts. This chiller season (fall of 2018- May 2019), PES has coated 74 chillers throughout the state of Texas.

Identifying the Problem

Early in the morning of March 11th we received a call from an HVAC contractor working at a hospital in Houston, Texas. The caller said he had heard we worked on corrosion control of chillers. However, they had a unique issue with a crack in the tube sheet that was allowing water to mix with Freon gasses.

We acknowledged we had a solution for this issue that had worked for us in the past. We informed the caller we would like to send a Technical Consultant to look at the problem, and then give a written quotation to make repairs. Within hours we were in front of the customer assessing their problem and offering ideas for a long term repair of the crack. We also provided a long term solution for all of the other corrosive issues they were facing on this heat exchanger.

Quoting the Repairs

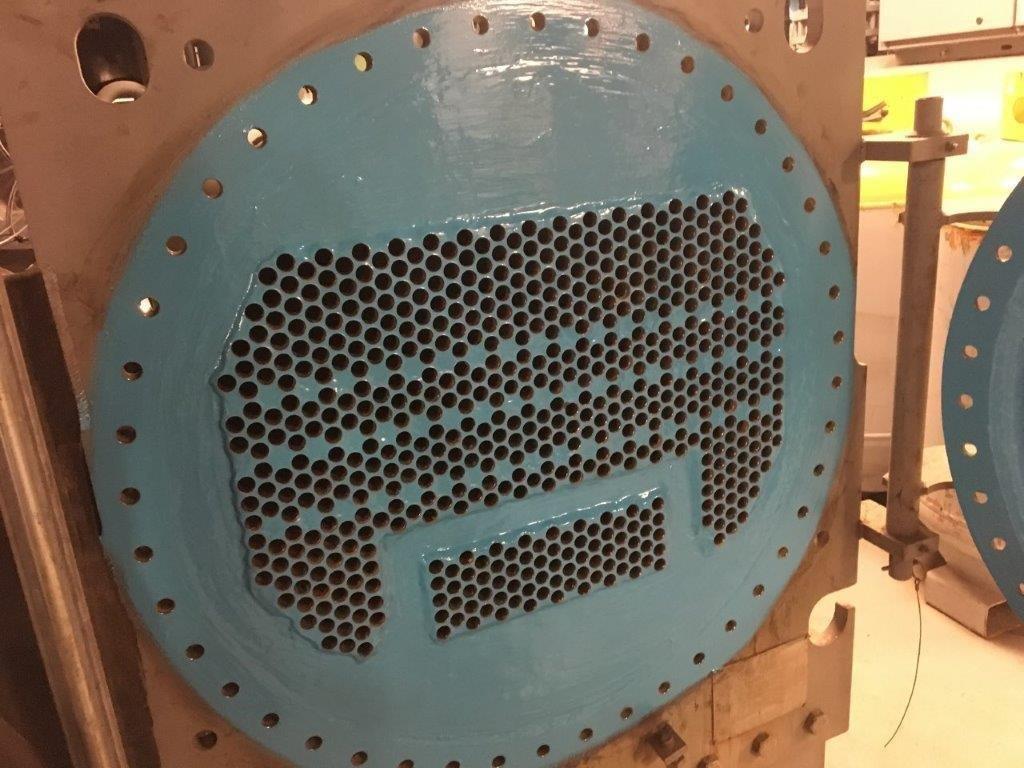

After accepting our quote, we dispatched one of our experienced crews. We implemented all of our safety and house cleaning duties. Additionally, we built a dust proof tent with a dust collector, installed protective plugs in copper alloy tubes to protect their internals, and removed all rust at the same time. This created a rough anchor profile of 3-4 mils for our protective coatings to lock into all metal substrates.

Applying PES 102 and PES 201

Once the surface prep was complete, we removed blasting plugs and installed coating corks. We then wiped down all surfaces with solvent to remove oils and dust. Then, we mixed up some (Polymeric Engineered Solutions) PES 102 Power Metal Fluid, a fluid version of our PES 101 Power Metal Paste. Then the customer turned on an already installed vacuum pump to the chiller condenser, which pulled the PES 102 into the cracks to seal them. Within a few minutes, we were able to cover both tube sheets and seal cracks. Once PES 102 was firm enough (approximately 30 minutes), we applied PES 201 Repair Paste, a ceramic filled paste grade repair compound. This coating was thick enough to bring coatings flush with the end of the tubes, along with the repair of any other eroded metal in and on other chiller components such as water boxes or division plates.

Applying PES 202 and PES 203

Next was the two coats of PES 202 Ceramic Repair Fluid. Then, one coat of PES 203 Super Flow Ceramic Fluid, a ceramic filled brushable coating at a thickness of 12-16 mils to aid in leaving a smooth, chemical resistant tough finish. After all coatings had reached enough curing time of 6-8 hours at 68°F, coating corks were tapped into tubes. The tubes were then honed to give a slight chamfer and corks were pulled.

All work was visually inspected and wet sponge tested, and no additional repairs were needed. In the event the inspection and sponge test reveal holidays (pinholes), they would be repaired and re-tested. All tubes were checked to make sure that no debris was left in them. The chiller is back on line performing in peak condition.

This is just one example of a project we did using power metals and ceramic coatings for repairs. We customize solutions and repair services depending on the severity and the type of problem. Contact us with the link below for more information or to get a quote on your next chiller repair project today!